Nā Kūlana: Ductile hao

Kaumaha: E like me ke kiʻi kiʻi

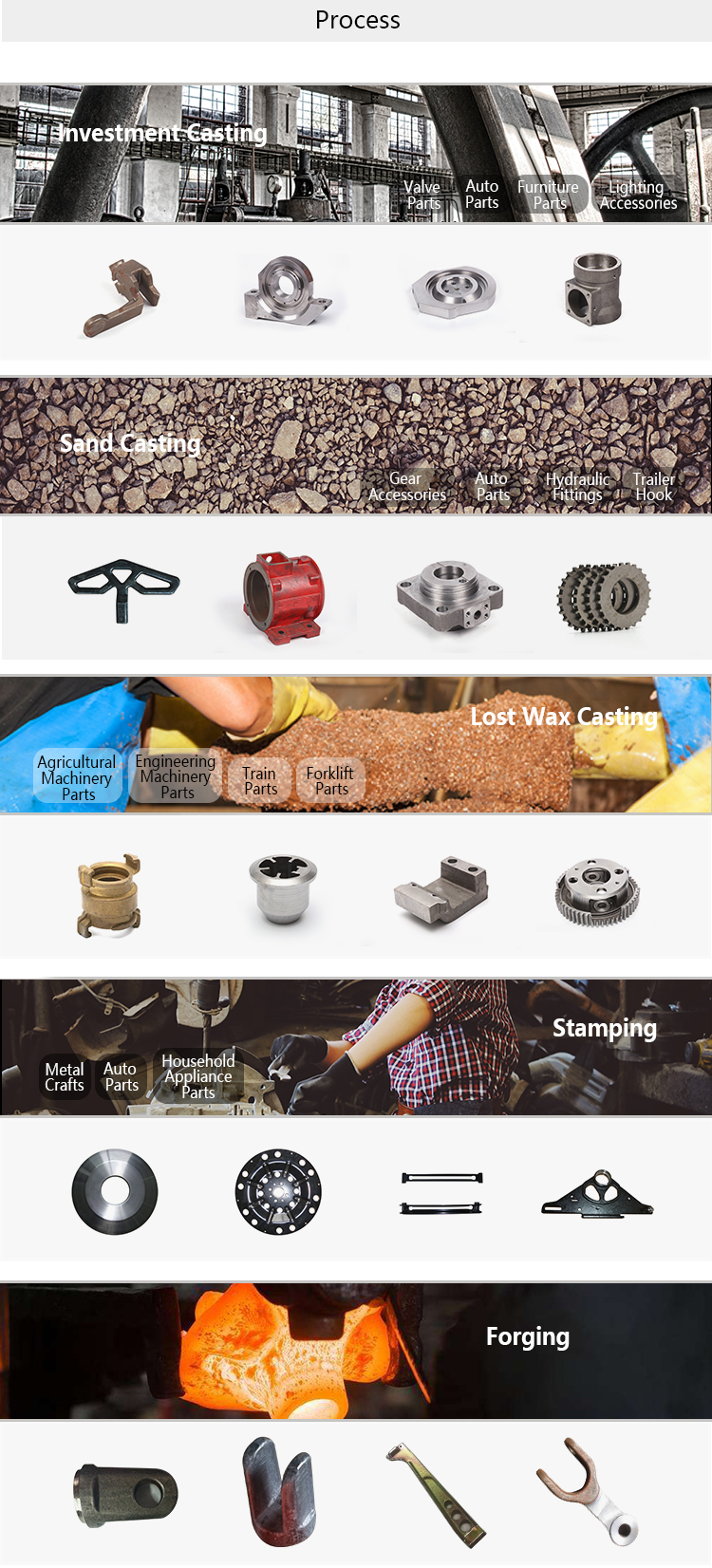

Kaʻina: Green Sanding Canding + Machining

Hao ~ 94%

Kaukaʻina 3.2 - 3.60%

Silicon 2.2 - 2.%

Manganese 0.1 - 0.2%

Holakihua 0.03 - 0.04%

Phosprus 0.005 - 0.04%

Sulfur 0.005 - 0.02%

Copic <= 0.40%

Paina:

ʻO ka GGG40-15-Sand e hoʻopaʻa ana i ka scaffolding scaffolding scamlock cramp

S caffold system e hiki ke hoʻohanaʻia no nāʻano āpau o ka loaʻaʻana o kahi kākoʻo kākoʻo a D

ʻO nāʻoihana, Faceade Reteent, HasdShore kūkulu, e pili ana iā EtUdDs etc.ʻO ia ka mea hopu, e hopu i nā kilokilo,

a iʻole nā apo, e hana i nā pilina wikiwiki a maikaʻi loa. Hiki ke hoʻokōʻia nā kihi'ē aʻe

He aha nāʻano huahana e hiki ai iā mākou ke hāʻawi?

|

Products

|

According to the customers' technical drawings or samples

|

|

Casting Material

|

Cast Iron, ductile iron, Grey iron, GG25, GG20, GGG40, GGG50, GGG60 GGG70:

|

|

QT400-18,QT450-10,0T600-3QT700-2,FCD400,FCD450,60-40-18,65-45-12,ect.

|

|

Casting Product Weight

|

available from 0.02kg to 3000kg

|

|

Surface Treatment

|

Oxidation

|

|

Plating zinc

|

|

Painting

|

|

Hot galvanized

|

|

Powder coating

|

|

Electroplating

|

|

Sand blasting

|

|

Electrophoresis

|

|

Vbration Grinding

|

|

Inspection

|

*100% ins pection before shipping, offer the material reports and mechanical property reports

|

|

*Control Plan and PPAP documents according to the clients'requirements

|

|

*ISO9001: 2015 quality control system

|

|

Extra Service

|

CNC machining servce in our machining workshop

|

|

Advantages

|

* The dimensions and outs ide shape are similar with investment casting

|

|

*The surface roughness is good from 2.5 to 25um(100 to 1000um

|

|

*The min thickness can meet 3 mm(0. 120inch)

|

|

*decrease the internal crack and keep close structure

|

|

*As no joint and defect the cleaning and machining work can be less

|

|

*it's cheaper because its a simpler process and the foam is cheaper than the wax

|